Enquire about "924 Small Wheel Loader" Now

924 Small Wheel Loader

Enjoy All Day Comfort

- Have a seat in the new Cat small wheel loader and enjoy automatic temperature control, class leading sound levels, enhanced all-around visibility and low-effort joystick controls that move with you on a fully adjustable seat suspension. A large spacious operator environment combined with Caterpillar hydraulic cylinder damping and smooth predictable controls make this the most comfortable seat on your jobsite.

- An upgrade to multi-view camera and rear object detection gives you an extra eye on the jobsite while the new optional force feedback joystick steering keeps you feeling confident on those long shifts. The operator not present function helps to isolate the machine if you leave the environment; while seat belt notifications give you a gentle reminder to buckle up.

Efficiently Powerful

- Experience the difference with an intelligent hydrostatic power train and industry leading fuel savings through a lower maximum engine speed working in combination with a new auto engine RPM mode. This provides efficiency as standard with a boost in power when you need it. Optimize traction and minimize wheel slip with a new Auto Wheel Torque system tuned to provide peak performance while maximizing tire life and keeping operating costs low. Track your production and accurately hit your load targets with Cat Payload.

Work Made Easy

- Move more with the Caterpillar patented quick loading performance series buckets and optimized Z-bar linkage with enhanced forward visibility that combines the digging efficiency of a traditional Z-bar with tool carrier capabilities. The parallel lift and high tilt forces throughout the working range allow you to confidently handle loads with precise control.

- Multi-function work has never been easier with dedicated pumps for each system and a flow sharing implement valve governed by an intelligent power management system. Simultaneously lift, steer, and drive without compromise. Upgrade to autolube to make service easy and get to work quicker. Light the way with auto roading lights that come on at night fall.

Customize Your Experience

- Meet your application requirements and individual preferences with Caterpillar industry first Hystat™ Operator Modes featuring four unique power train settings. Select classic torque converter for smooth rollout, conventional hystat for aggressive engine braking, an ice mode that maximizes your control on slippery underfoot, and an all new single pedal mode for simplified use.

- Fine tune machine performance with adjustments at your fingertips through programmable joysticks, soft touch buttons, and a new jog dial that works in combination with a standard touch screen display. Quickly recall attachment profiles that maintain key settings for versatility onthe jobsite and optimal efficiency.

Upgrades and Services

- Enjoy a full range of upgrades and accessories to configure your small wheel loader for a broader range of applications.

- Utilize readily available services and maintenance parts including a range of self-service options (SSO) and dealer installed kits.

| Engine | |

|---|---|

| Rated Engine Power - ISO 14396 | 105 kW (141 hp) |

| Engine Model | Cat C7.1* |

| Performance Mode | Automatic |

| Rated Gross Power - Rated Engine Speed | 1800 r/min (1800 r/min) |

| Rated Engine Power - ISO 14396 (DIN) | 143 mhp (143 mhp) |

| Rated Net Power - SAE J1349 at Minimum Fan Speed | 102 kW (137 hp) |

| Rated Net Power - ISO 9249 at Minimum Fan Speed | 102 kW (137 hp) |

| Rated Net Power - ISO 9249 (DIN) at Minimum Fan Speed | 140 mhp (140 mhp) |

| Maximum Gross Torque - Engine Speed | 1400 r/min (1400 r/min) |

| Maximum Gross Torque - ISO 14396 | 725 N·m (534 ft·lbf) |

| Maximum Net Torque - SAE J1349 | 704 N·m (519 ft·lbf) |

| Maximum Net Torque - ISO 9249 | 711 N·m (524 ft·lbf) |

| Displacement | 7.01 l (427 inu00b3) |

| Bore | 105 mm (4 in) |

| Stroke | 135 mm (5 in) |

| Note | *Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA. |

| Note (1) | Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (2) | Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when engine is equipped with alternator, air cleaner, emission components and fan at specified speed. |

| Weights | |

|---|---|

| Operating Weight | 11775 kg (25960 lb) |

| Buckets | |

|---|---|

| Bucket Capacities | 1.9-5.0 m3 (2.5-6.5 yd3) |

| Steering | |

|---|---|

| Steering Cylinder - Bore Diameter | 70 mm (2.8 in) |

| Steering Cylinder - Rod Diameter | 40 mm (1.6 in) |

| Steering Cylinder - Stroke | 438 mm (17.2 in) |

| Maximum Flow - Steering Pump | 125 L/min (33 gpm) |

| Maximum Working Pressure - Steering Pump | 24130 kPa (3500 psi) |

| Steering Cycle Times (Full Left to Full Right) - Minimum RPM: Pump Flow Limited | 2.8 s (2.8 s) |

| Steering Cycle Times (Full Left to Full Right) - Maximum RPM: 90 RPM Steering Wheel Speed | 2.4 s (2.4 s) |

| Loader Hydraulic System | |

|---|---|

| Maximum Flow - Implement Pump | 150 L/min (40 gpm) |

| Maximum Flow - Implement Pump - 3rd Function Maximum Flow* | 150 L/min (40 gpm) |

| Maximum Flow - Implement Pump - 4th Function Maximum Flow* | 150 L/min (40 gpm) |

| Maximum Working Pressure - Implement Pump | 26000 kPa (3771 psi) |

| Relief Pressure - Tilt Cylinder | 28000 kPa (4061 psi) |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure | 26000 kPa (3771 psi) |

| Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure | 28000 kPa (4061 psi) |

| Lift Cylinder: Standard Lift Linkage - Bore Diameter | 110 mm (4.3 in) |

| Lift Cylinder: Standard Lift Linkage - Rod Diameter | 60 mm (2.4 in) |

| Lift Cylinder: Standard Lift Linkage - Stroke | 728 mm (28.7 in) |

| Tilt Cylinder: Standard Lift Linkage - Bore Diameter | 130 mm (5.1 in) |

| Tilt Cylinder: Standard Lift Linkage - Rod Diameter | 70 mm (2.8 in) |

| Tilt Cylinder: Standard Lift Linkage - Stroke | 555 mm (21.9 in) |

| Hydraulic Cycle Time - Raise, Ground Level to Maximum Lift | 5.4 s (5.4 s) |

| Hydraulic Cycle Time - Dump (at Maximum Lift Height) | 1.5 s (1.5 s) |

| Hydraulic Cycle Time - Float Down, Maximum Lift to Ground Level | 2.6 s (2.6 s) |

| Hydraulic Cycle Time - Total Cycle Time | 9.5 s (9.5 s) |

| Note | *3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display when equipped. |

| Service Refill Capacities | |

|---|---|

| Fuel Tank | 195 l (51.5 gal (US)) |

| Cooling System | 32 l (8.5 gal (US)) |

| Engine Crankcase | 19.5 l (5.2 gal (US)) |

| Transmission - Gear Box | 8.5 l (2.2 gal (US)) |

| Front Axles | 21 l (5.5 gal (US)) |

| Rear Axles | 21 l (5.5 gal (US)) |

| Hydraulic System - Including Tank | 160 l (42.3 gal (US)) |

| Hydraulic Tank | 90 l (23.8 gal (US)) |

| Transmission | |

|---|---|

| Forward and Reverse - Range 1* | 1-13 km/h (0.6-8 mph) |

| Forward and Reverse - Range 2 | 13 km/h (8 mile/h) |

| Forward and Reverse - Range 3 | 27 km/h (17 mile/h) |

| Forward and Reverse - Range 4 | 40 km/h (25 mile/h) |

| Note | *Creeper control allows maximum speed range adjustability from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display when equipped. Factory default is 7 km/h (4.4 mph). |

| Tires | |

|---|---|

| Standard Size | 20.5 R25, radial (L-3) |

| Other Choices Include | 17.5 R25, radial (L-3), 17.5-25 16 PR (L-3), 20.5-25 16 PR (L-3) |

| Note (1) | Other tire choices are available. Contact your Cat dealer for details. |

| Note (2) | In certain applications, the loaderu2019s productive capabilities may exceed the tireu2019s tonnes-km/h (ton-mph) capabilities. |

| Note (3) | Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. |

| Cab | |

|---|---|

| ROPS | ISO 3471:2008 |

| FOPS | ISO 3449:2005 LEVEL II |

| Axles | |

|---|---|

| Front | Fixed; Open differential (standard); Locking differential (optional) |

| Rear | Oscillating u00b1 11 degrees; Open differential (standard); Limited slip differential (optional) |

| Air Conditioning System | |

|---|---|

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.99 tons). |

| Sound | |

|---|---|

| Operator Sound Pressure (ISO 6396:2008) | 68 dB(A) (68 dB(A)) |

| Average Exterior Sound Pressure (ISO 6395:2008) | 101 dB(A) (101 dB(A)) |

| Note (1) | Measurements were conducted with properly installed and maintained cab doors and windows closed. |

| Sustainability | |

|---|---|

| Recyclability | 95% |

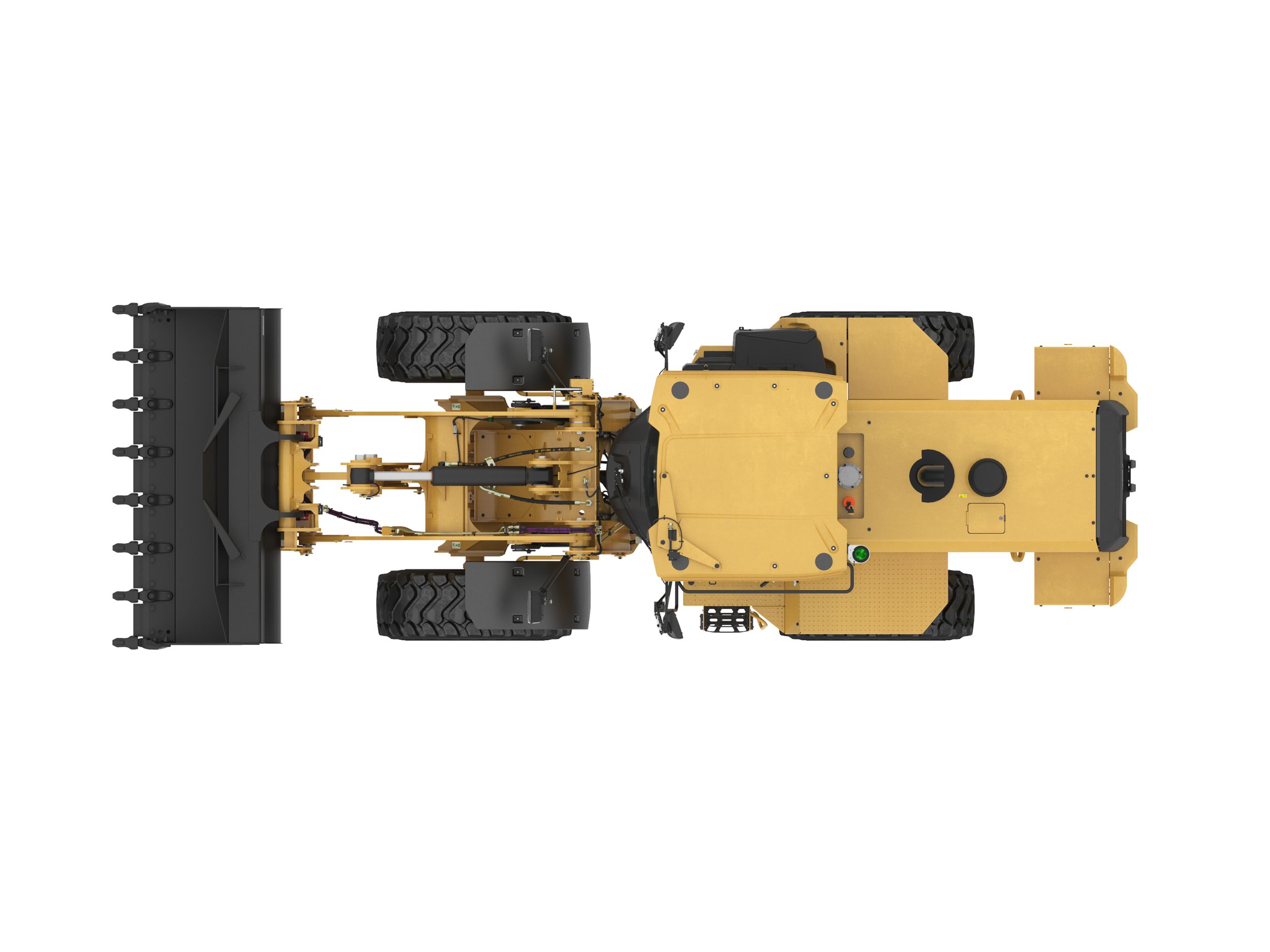

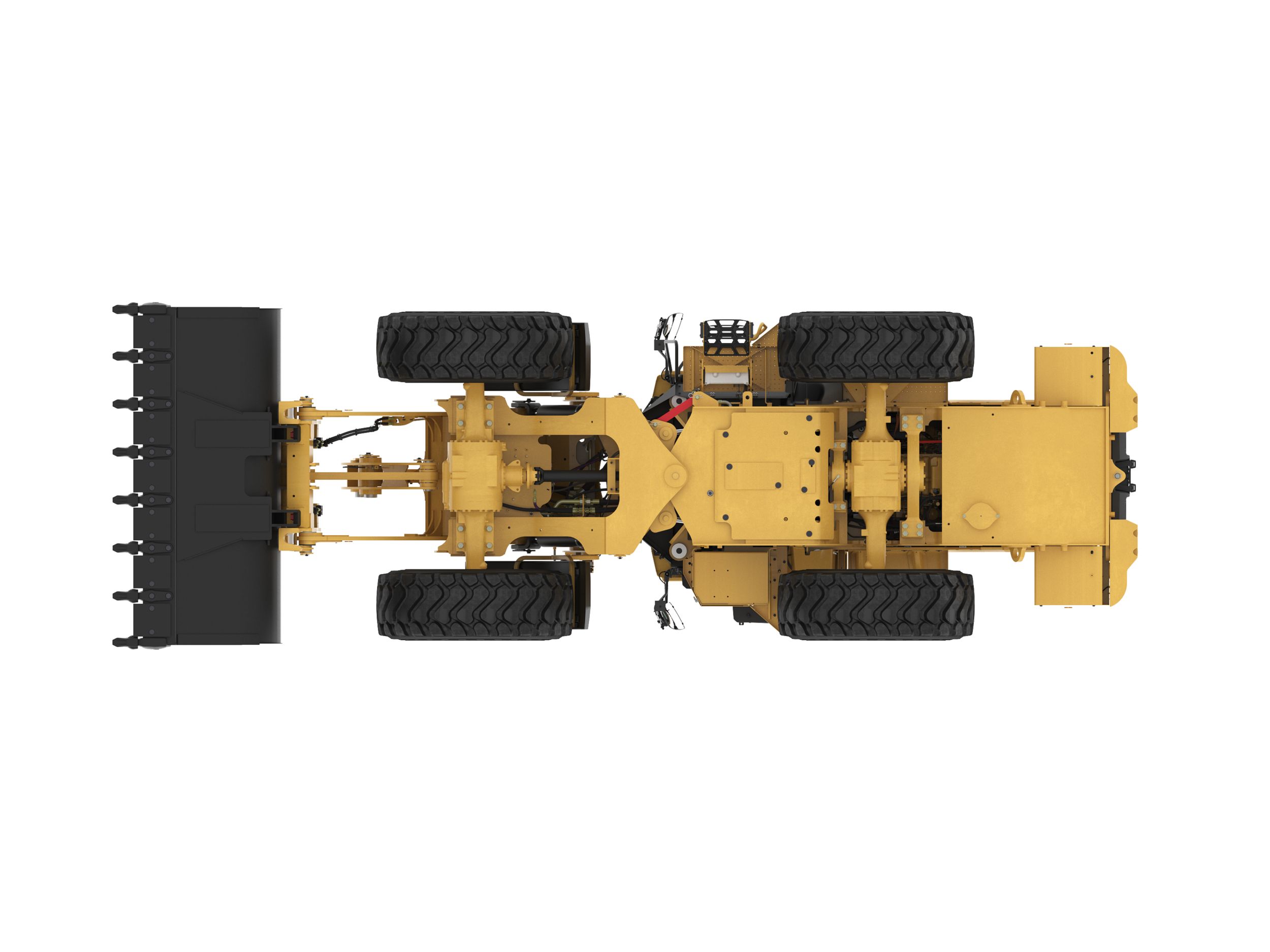

| Dimensions with Bucket - Standard Lift | |

|---|---|

| Height - Ground to Cab** | 3340 mm (131.5 in) |

| Height - Ground to Beacon** | 3707 mm (146 in) |

| Height - Ground to Axle Center** | 685 mm (26.9 in) |

| Height - Ground Clearance** | 397 mm (15.6 in) |

| Length - Overall* | 7418 mm (292 in) |

| Length - Rear Axle to Bumper | 1958 mm (77 in) |

| Length - Hitch to Front Axle | 1500 mm (59 in) |

| Length - Wheel Base | 3000 mm (118.1 in) |

| Clearance - Bucket at 45u00b0* | 2801 mm (110.2 in) |

| Clearance - Load over Height** | 3308 mm (130.2 in) |

| Clearance - Level Bucket** | 3526 mm (138.8 in) |

| Height - Bucket Pin** | 3853 mm (151.6 in) |

| Height - Overall** | 5068 mm (199.5 in) |

| Reach - Bucket at 45u00b0* | 990 mm (38.9 in) |

| Carry Height - Bucket Pin | 402 mm (15.8 in) |

| Dig Depth** | 100 mm (3.9 in) |

| Width - Bucket | 2550 mm (100.4 in) |

| Width - Tread Center | 1933 mm (76.1 in) |

| Turning Radius - Over Bucket | 5916 mm (232.9 in) |

| Width - Over Tires | 2543 mm (100 in) |

| Turning Radius - Outside of Tires | 5404 mm (212.7 in) |

| Turning Radius - Inside of Tires | 2850 mm (112.2 in) |

| Rack Angle at Full Lift | 53 u00b0 (53 u00b0) |

| Dump Angle at Full Lift | 49 u00b0 (49 u00b0) |

| Rack Angle at Carry | 42 u00b0 (42 u00b0) |

| Departure Angle | 33 u00b0 (33 u00b0) |

| Articulation Angle | 40 u00b0 (40 u00b0) |

| Tipping Load - Straight (ISO 14397-1:2007)* | 8652 kg (19075 lb) |

| Tipping Load - Full Turn (ISO 14397-1:2007)* | 7499 kg (16533 lb) |

| Breakout* | 9646 kg (21266 lb) |

| Operating Weight | 11775 kg (25960 lb) |

| Note (1) | *Vary with bucket. |

| Note (2) | **Vary with tire. |

| Note (3) | Dimensions listed are for a machine configured with standard counterweights, 20.5 tires, 80 kg (176 lb) operator, and power train guard. Values are listed for a 2.1 m3 (2.7 yd3) pin on, general purpose performance series bucket with bolt-on cutting edge. |

Standard Equipment

- NOTE: Not all features are available in all regions.

- OPERATOR ENVIRONMENT

- 75 mm (3 in) retractable seatbelt

- Automatic temperature control

- Cab, enclosed ROPS/FOPS pressurized and sound suppressed

- Push to Start

- 8 Inch Touch Screen

- Programmable Joystick

- Cup holders

- External mirrors with lower parabolic

- Ground level cab door release

- Hydraulic control lockout

- Interior cab lighting, door

- Lunch box storage

- Radio ready speakers

- Seat mounted electronic implement controls, adjustable

- Sliding glass on side window

- Column mounted multi function control lights, wipers, turn signal

- Suspension seat, fabric

- Tilt steering wheel

- Tinted front glass

- Wet arm wiper/washer, 2-speed and intermittent, front

- Wet arm wiper washer, rear

- Mounting Provision

- Digital hour meter, odometer and tachometer

- Digital ground speedometer and direction indicator

- Engine coolant temperature gauge

- Fuel and diesel exhaust fluid levels

- Hydraulic oil temperature gauge

- Fuel and diesel exhaust fluid levels

- Hydraulic oil temperature gauge

- POWER TRAIN

- Cat C7.1 engine

- Auto idle shut down feature

- Auto Engine RPM

- Meets Brazil MAR-1 emission standards, equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- Turbocharged and aftercooled

- Filtered crankcase breather

- Power Modes (standard and performance)

- Dry type air cleaner

- Coolant protection to –34 °C (–29 °F)

- Fuel priming pump, automatic

- Fuel water separator

- Axle seal guards

- Enclosed wet disc full hydraulic brakes

- Parking brake, electric

- Lubed for life driveshafts

- Hydrostatic transmission with electronic control

- Operator modes (TC, Hystat, Single Pedal and Ice)

- Directional shift aggressiveness (fast, medium, slow)

- Auto Wheel Torque control, adjust wheel torque

- Creeper control, adjust ground speed

- Single plane cooling package, wide 6 fins per inch density

- Hydraulically driven demand cooling fan

- Scheduled Oil Sampling (S·O·SSM) port, engine, coolant, transmission

- HYDRAULICS

- Automatic lift and bucket kickouts, adjustable in-cab

- Bucket and fork modes, adjustable in-cab

- Cylinder damping at kickout and mechanical end stops

- Fine mode control (fast, medium, slow)

- Hydraulic response setting (fast, medium, slow)

- Hydraulic diagnostic connectors and S·O·S ports

- Hydraulic sight gauge, visible

- Load sensing hydraulics and steering

- Seat mounted hydraulic joystick controls

- ELECTRICAL

- Alternator, 115-amp, heavy duty

- 12V power supply in cab (2)

- Batteries, 1,000 CCA (2) 24-volt system, disconnect switch

- Back up alarm

- Emergency shutdown switch

- LED rear stop and turn lights

- Heavy duty gear reduction starter

- Product Link™

- Remote jump start post

- Resettable main and critical function breakers

- Roading lights front and rear

- OTHER

- Large-access enclosure doors with adjustable close/open force

- Parallel lift loader linkage

- Recovery hitch with pin

- Remote mounted lubrication points

- Lockable compartments

Optional Equipment

- NOTE: Not all features are available in all regions.

- OPERATOR ENVIRONMENT

- Joystick steering – 25 mph (40 kph) capable

- Radio packages

- Telescoping Steering Column

- Deluxe seat – fully adjustable fabric air suspension seat with mid seat backrest

- Premium seat – fully adjustable leather and fabric air suspension with high backrest and air lumbar support. Seat is heated and ventilated on bottom cushion and backrest.

- Rear Object Detection

- Multi View Camera

- Front View Camera, roof mounted

- Heated external Mirrors (2)

- Electrically adjustable and heated external mirrors (2)

- Internal Mirrors (2)

- Sunscreen, front and rear

- Operator Not Present sytem

- Powered precleaned for cab air

- Cab guarding

- POWER TRAIN

- Differential, limited slip, rear

- Differntial lock in front axle

- Powertrain Guarding

- Range of Tire Options

- Fenders (extended cover and full coverage)

- HYDRAULICS

- Auxiliary flow, third and fourth function

- Connect Under Pressure Disconnects

- Ride Control System, adjustable via display

- Autolube, integrated in display

- Debris packages (low, medium, high)

- ELECTRICAL

- Cold start package

- Ether starting aid, block heater and additional batteries, 1,000 CCA (4 total)

- Lights, auxiliary, halogen or LED with engine compartment lights

- Beacon light, strobe

- Light Guarding

- OTHER OPTIONAL EQUIPMENT

- Coupler (Fusion)

- Heavy Counterweight

- Cat Payload Printer

- Cylinder Guarding

- Range of Work Tool Attachments